|

| Repair Articles |

|---|

| Ask The Repairman |

| Repair Blue Book |

| Hardware Parts Accessories |

| Electronics |

| Guitar Wood and Kits |

| Tools |

| Friends |

|

|

|

|

|

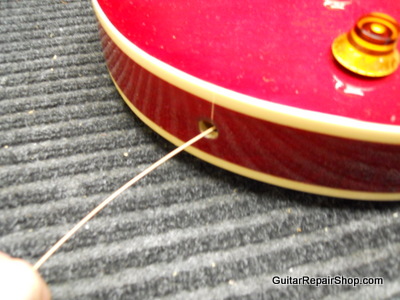

Thinbody Repair TechniquesBy Steve Carmody c. 2015Thin-body guitars such as the Gibson ES 335 pose a challenge when doing repairs such as jack and pot installation, as well as structural repairs. They are just too thin to get anything more than a couple fingers inside the body of the guitar. So how can you remove and install these components, or do structural repairs? In some cases, such as major damage to the body, removing the back of one of these models might be justified, but certainly not if all you need to do is replace a jack. Here is how I do it: For jack installation I have created a tool from a length of guitar string. I soldered a one inch length through the ball end of the string. I used a .054 wound string since it gives enough stiffness to be easy to direct through the body to the jack hole.

I then slide the modified string through jack and pull it until the soldered cross-piece of string anchors against the jack.

Then I slide the other end of the string into the F-hole, through the body and out the jack hole.

I can then draw the jack into the hole, slide the washer and nut down the string to the exposed threads, and tighten the nut by hand while holding the jack in place with the modified string tool. Once the nut is tight I push the string back into the body and fish it out by way of the F-hole. Makes an otherwise challenging job quite easy.

Using the same basic technique, long rubber bands, surgical tubing and even string can be used to re-install other components into thin body guitars, as seen in this photograph.

Finally, the string tool can also be used to install side patches into fractured side panel damage, as seen in the photographs below. In this case I used the string tool to draw a patch into the correct location at the jack hole area. I had already drilled a 3/8 inch hole in the patch. Once the patch was correctly positioned, I slipped in a bolt by way of the F hole, and using a plexiglass caul on the outside clamped the interior side patch with a nut. This also evened-out the displaced side fracture.

Steve Carmody is an independant guitar repairman and luthier with a shop in Silver Spring, Md. He has been doing guitar repair and restoration full-time since 1990. Questions about this article or anything else related to guitar repair? Send e-mail to - GuitarRepairShop@aol.com |